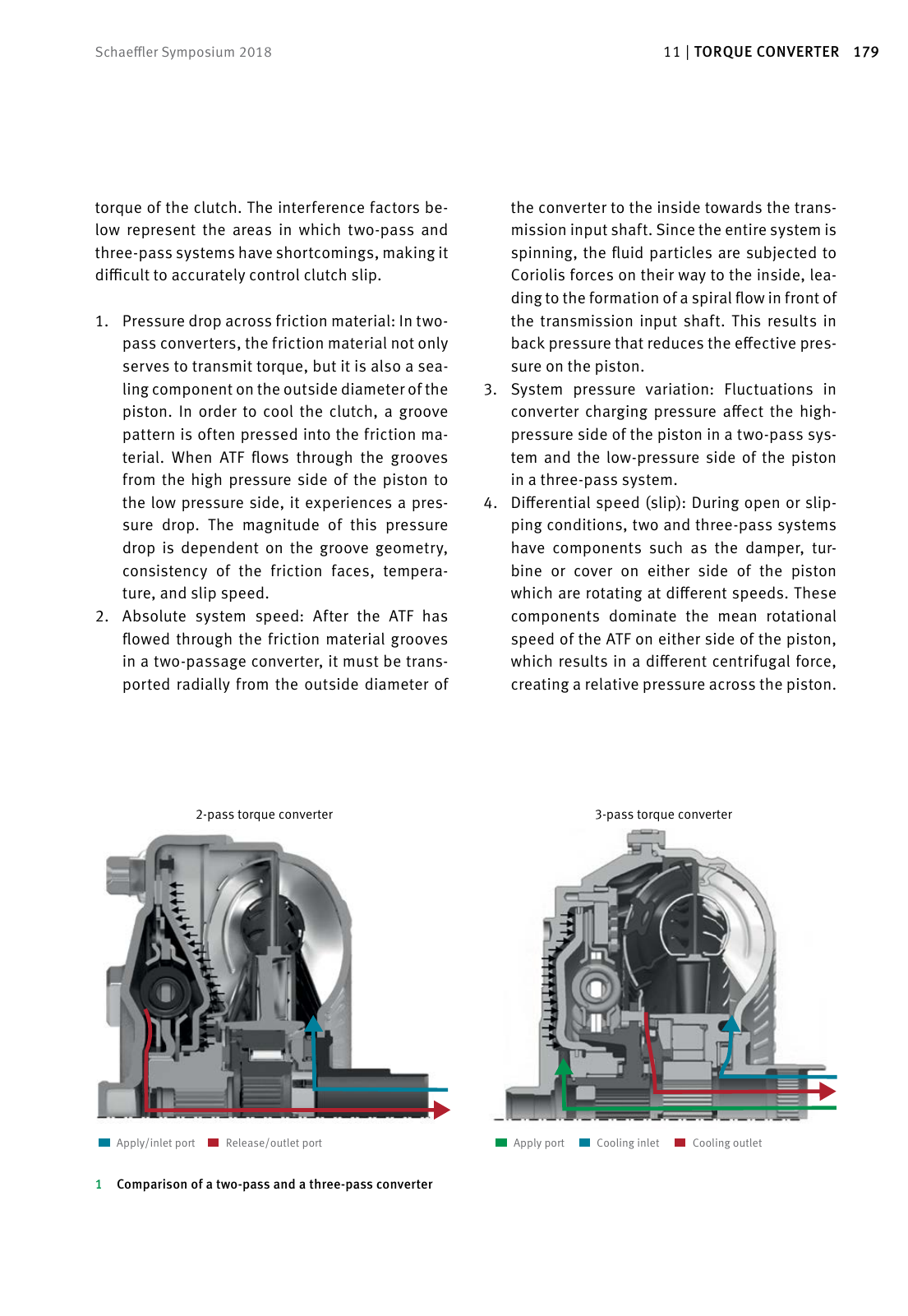

178 TO R Q U E CO N V E RT E R 11 17911 TO R Q U E CO N V E RT E RSchaeffler Symposium 2018 torque of the clutch The interference factors be low represent the areas in which two pass and three pass systems have shortcomings making it difficult to accurately control clutch slip 1 Pressure drop across friction material In two pass converters the friction material not only serves to transmit torque but it is also a sea ling component on the outside diameter of the piston In order to cool the clutch a groove pattern is often pressed into the friction ma terial When ATF flows through the grooves from the high pressure side of the piston to the low pressure side it experiences a pres sure drop The magnitude of this pressure drop is dependent on the groove geometry consistency of the friction faces tempera ture and slip speed 2 Absolute system speed After the ATF has flowed through the friction material grooves in a two passage converter it must be trans ported radially from the outside diameter of Introduction In the automotive industry the global trend to fa vor more efficient systems continues with the goal to further reduce CO2 emissions As a result internal combustion engines continue to be opti mized through the extensive use of cylinder deac tivation and turbocharging It is not just the weight of the complete vehicle and thus of the drive train that must be reduced but also the mass moment of inertia of the components in or der to offer improved driving dynamics and to rapidly reach the optimum efficiency operating point of turbocharged engines Schaeffler offers technologies that improve the ef ficiency of the transmission through reduced los ses while also allowing the use of new engine tech nology In terms of the requirements for the torque converter lock up clutch and damper this means that vibration isolation becomes significantly more challenging 1 One potential solution could be light weight components and another could be the intelligent integration of existing masses into the system to isolate the vibrations In addition the reduction of CO2 emissions also requires a lock up clutch that is capable of pre cisely controlling slip in all operating conditions In new generation transmissions there has been a tendency to increase the number of gears re sulting in additional reductions of installation space for the torque converter This paper aims to show technical solutions for the challenges described above Four passage torque converter Initial situation The ability to control the lock up clutch in the con verter is essential for the efficiency and vibration isolation of the system It is important to ensure that the clutch can be opened or closed on de mand in all operating conditions and that the tar geted slip speed can be maintained precisely Al lowing slip in the torque converter clutch is an effective method to reduce drivetrain vibration however efficiency is lost in the form of heat as a function of increased slip speed The torque converter clutch is controlled by ap plying fluid pressure to the piston Traditionally there are two passage and three passage sys tems With the two passage converter the clutch is activated by reversing the flow of the automatic transmission fluid ATF through the converter With the three passage converter two passages are used for ATF circulation through the torus and to cool the clutch while the third is used inde pendently to control the lock up clutch Figure 1 shows a comparison of two pass and three pass torque converters In simple terms the torque converter clutch ca pacity is characterized by the following The active surface area of the piston the effec tive radius of the friction material and the num ber of friction surfaces The friction coefficient between the friction ma terial and steel The pressure applied to the piston While the geometry and the friction coefficient of a given design are fixed the pressure that con trols the clutch can be varied by the hydraulic control system of the transmission In an ideal system the torque capacity of the clutch and the required slip would be controlled exclusively by varying the apply pressure Torque converter clutch interference factors In reality there is no ideal system because there are other factors that affect the transmitted the converter to the inside towards the trans mission input shaft Since the entire system is spinning the fluid particles are subjected to Coriolis forces on their way to the inside lea ding to the formation of a spiral flow in front of the transmission input shaft This results in back pressure that reduces the effective pres sure on the piston 3 System pressure variation Fluctuations in converter charging pressure affect the high pressure side of the piston in a two pass sys tem and the low pressure side of the piston in a three pass system 4 Differential speed slip During open or slip ping conditions two and three pass systems have components such as the damper tur bine or cover on either side of the piston which are rotating at different speeds These components dominate the mean rotational speed of the ATF on either side of the piston which results in a different centrifugal force creating a relative pressure across the piston 2 pass torque converter 3 pass torque converter Apply inlet port Release outlet port Apply port Cooling inlet Cooling outlet 1 Comparison of a two pass and a three pass converter

Hinweis: Dies ist eine maschinenlesbare No-Flash Ansicht.

Klicken Sie hier um zur Online-Version zu gelangen.

Klicken Sie hier um zur Online-Version zu gelangen.