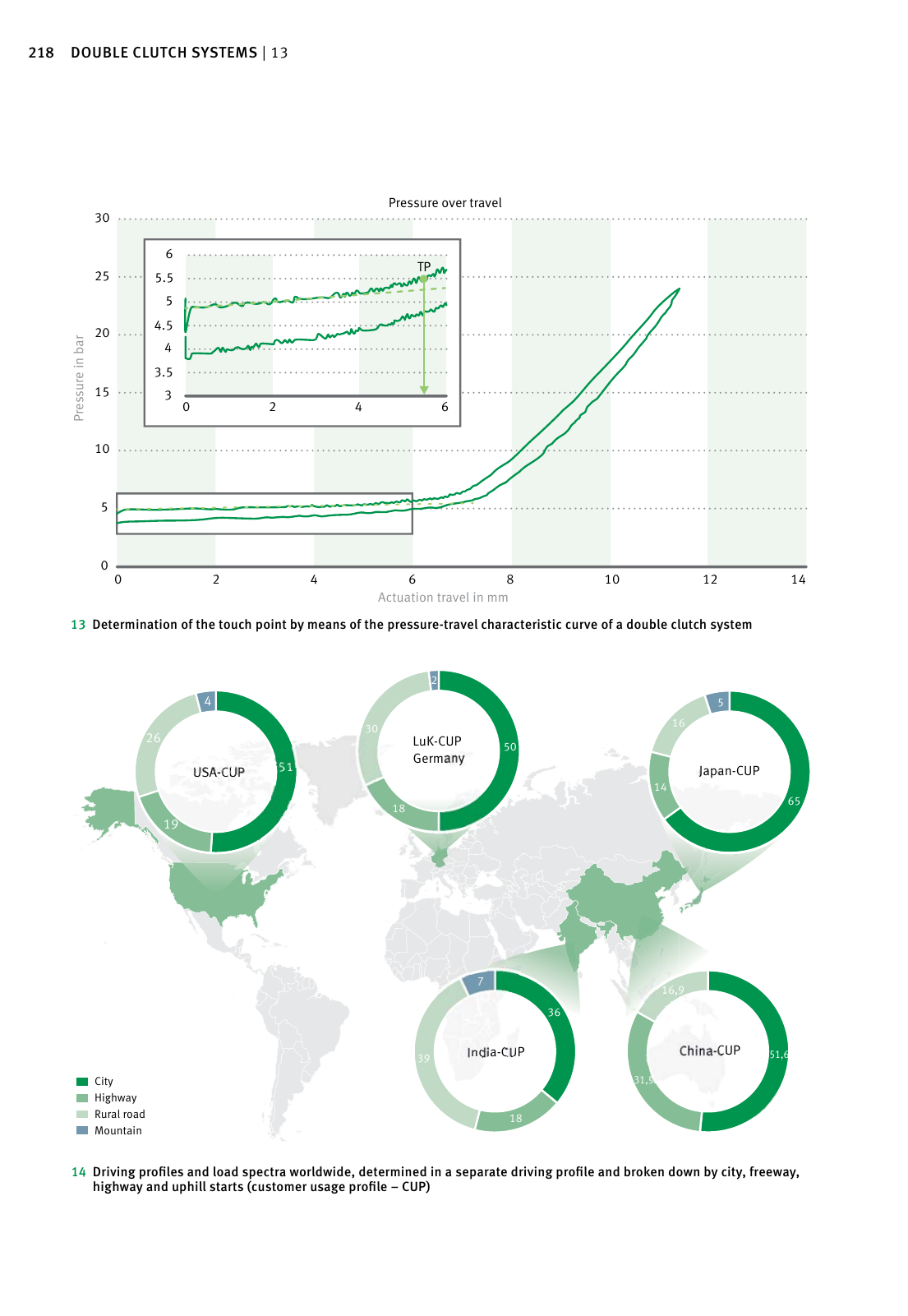

218 DOUBLE CLUTCH SYSTEMS 13 21913 DOUBLE CLUTCH SYSTEMSSchaeffler Symposium 2018 refers to the point at which the clutch be gins to transmit the torque When analy zing the touch point here at 10 Nm with re gard to its hysteresis on the pressure and travel characteristic curve we find that the travel hysteresis with 2 Nm is much lower than the pressure hys teresis with 13 Nm Since both the travel and the pressure signal may be available in a hydrostatic actuation as shown in Figure 13 the touch point be determined exclusive ly by these two actuator signals This is the sys tem s controllability advantage The touch point can be determined online in the vehicle without any clutch torque transmission In addition touch point point determination is independent from other input parameters such as the torque signal from the internal combustion engine For the reasons stated above touch point determination is relevant for systems capable of stop start opera tion and due to the increasing electrification of the powertrain Evaluation of system losses For technical evaluations Schaeffler not only re lies on test stand based consumption cycles such as NEDC or WLTP but for years has used its own real driving cycle that addresses local differences between markets around the world 6 Figure 14 Depending on the traffic situation this real dri ving cycle can meet the criteria for an RDE mea surement published by the EU 10 The losses evaluated for each component are shown in Figure 15 The following systems available on the market are compared in order to compare system losses Hydraulic wet double clutch with rotary feedthroughs actuation of the clutch and the transmission as well as cooling the clutch via a modern hydraulic system Power pack wet double clutch with engage ment bearings actuation of the clutch and the transmission as well as cooling of the clutch via a power pack Hydrostatic wet double clutch with engage ment bearings actuation of the clutch via a hy drostatic actuator actuation of the transmis sion via an electromechanical transmission actuator and cooling of the clutch via an elec tric pump The Hydrostatic system favored by Schaeffler has the smallest power loss compared to competi tors products From the real driving cycle an average engine speed of 1 800 rpm has been determined from a state of the art double clutch system The speeds in the NEDC are much lower For this reason two average speeds are compared to show the impact of cycle Crankshaft speed of 1 000 rpm and 1 800 rpm 13 Determination of the touch point by means of the pressure travel characteristic curve of a double clutch system 0 0 2 4 6 8 10 12 14 5 10 15 20 0 2 4 6 25 30 TP Actuation travel in mm 3 3 5 4 4 5 5 5 5 6 Pr es su re in b ar Pressure over travel 14 Driving profiles and load spectra worldwide determined in a separate driving profile and broken down by city freeway highway and uphill starts customer usage profile CUP 50 18 30 2 65 14 16 5 51 19 26 4 51 6 31 5 16 9 Highway City Rural road Mountain LuK CUP Germany Japan CUPUSA CUP 36 18 39 7 India CUP China CUP 15 Components analyzed and their power losses Power input Power output Drag torque of clutches and clutch cooling Drag torque of clutch apply bearing concepts Electric power consumption of actuation and control unit

Hinweis: Dies ist eine maschinenlesbare No-Flash Ansicht.

Klicken Sie hier um zur Online-Version zu gelangen.

Klicken Sie hier um zur Online-Version zu gelangen.