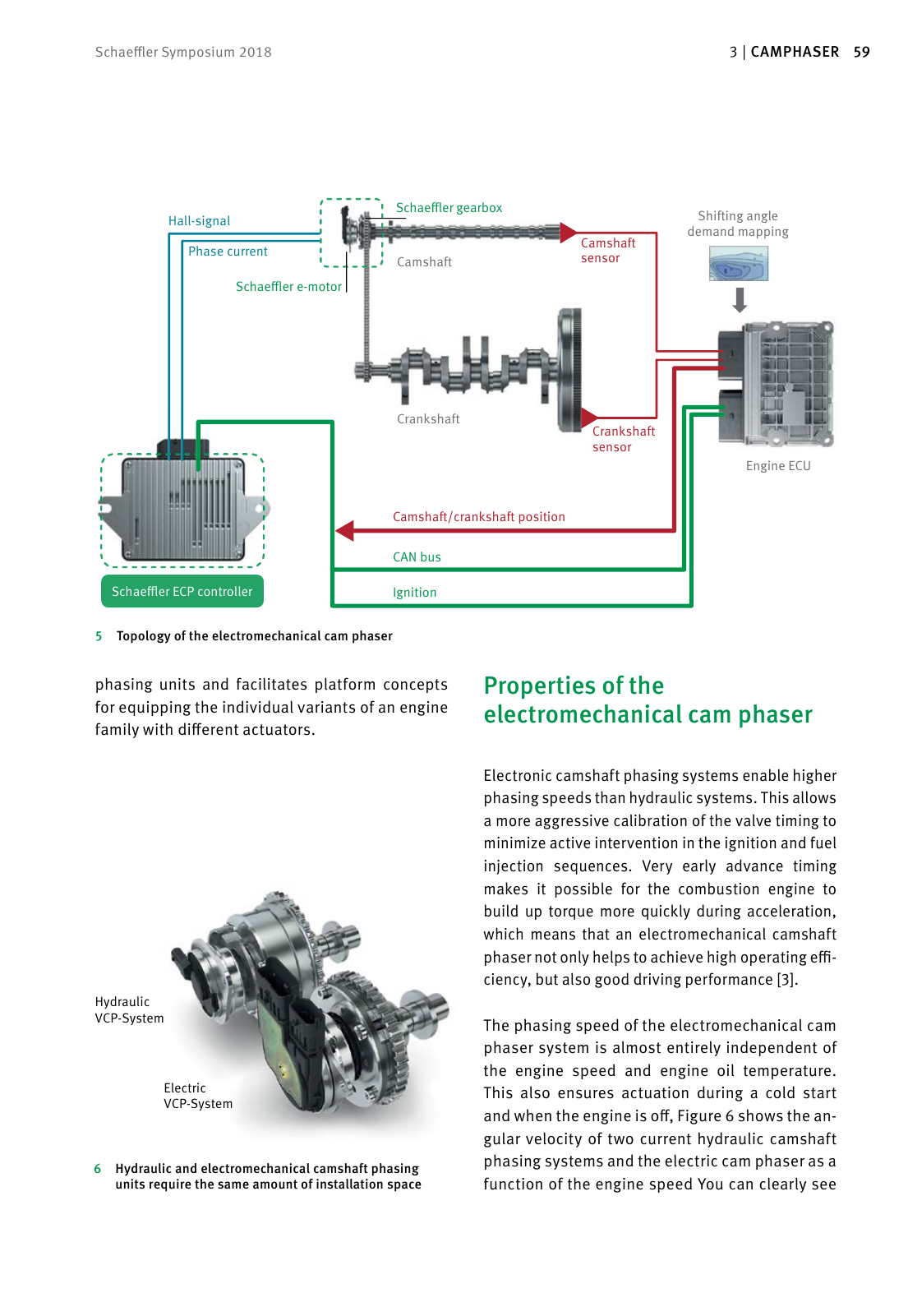

58 CA MPH A S E R 3 593 C A MPH A S E RSchaeffler Symposium 2018 phasing units and facilitates platform concepts for equipping the individual variants of an engine family with different actuators Properties of the electromechanical cam phaser Electronic camshaft phasing systems enable higher phasing speeds than hydraulic systems This allows a more aggressive calibration of the valve timing to minimize active intervention in the ignition and fuel injection sequences Very early advance timing makes it possible for the combustion engine to build up torque more quickly during acceleration which means that an electromechanical camshaft phaser not only helps to achieve high operating effi ciency but also good driving performance 3 The phasing speed of the electromechanical cam phaser system is almost entirely independent of the engine speed and engine oil temperature This also ensures actuation during a cold start and when the engine is off Figure 6 shows the an gular velocity of two current hydraulic camshaft phasing systems and the electric cam phaser as a function of the engine speed You can clearly see Output gear CamshaftInput gear Sprocket Coupling Wave generator Flex ring Shif ti n g an g le dema nd mapping Shifting angl e demand mappin g Hall signal Phase current Schaeffler E CP c ontrolle r Schaeffler gearbox Schaeffler e motor Engine EC U Camshaft sensorCamshaft Crankshaft Crankshaft sensor C amshaft crankshaft position CAN bus Ignition4 Design of the gear set for the electromechanical cam phaser 5 Topology of the electromechanical cam phaser Hydraulic VCP System Electric VCP System 6 H y draulic and electromechanical camshaft phasing units require the same amount of installation space 3 The electromechanical camshaft phaser the wave generator in conjunction with the flex ring Figure 4 The flex ring of the wave generator connects the sprocket via the input gearwheel and the output gearwheel with the camshaft The output gear wheel has two more teeth than the input gear wheel The wave generator presses the toothed flex ring into both gearwheels As the wave gene rator rotates the different number of gear teeth on the gearwheels produce the reduction ratio of the gear set 2 The electric motor is connected to an ECP control unit which regulates the motor s operating speed and processes the Hall sensor signals from the motor Figure 5 The sensors integrated in the electric motor de tect the position of the rotor and monitor tempe ratures The ECP control unit communicates with the engine control unit The target angle values of the camshaft are sent by CAN bus to the ECP con trol unit which compares it against the current position The electromechanical cam phaser switches between the three operating modes of advance timing constant phase angle and retard timing To realize an advance timing adjustment the e motor rotates more quickly than the cam shaft and to retard timing it rotates at a slower speed The constant angle is maintained by rota ting the output shaft of the electric motor at cam shaft speed As the level of hybridization increases the availa ble space in the engine compartment of modern vehicles decreases Therefore one of the main de velopment targets was to engineer an actuator system that is very compact The electric cam phaser fits within the space of a conventional hydraulic actuator without the need for modifications Figure 6 Modular interchangeability makes it easy to switch between hydraulic and electric camshaft

Hinweis: Dies ist eine maschinenlesbare No-Flash Ansicht.

Klicken Sie hier um zur Online-Version zu gelangen.

Klicken Sie hier um zur Online-Version zu gelangen.